How To Use 3M VHB Tape To Get More Strong?

3M VHB tape has become the go-to permanent bonding solution for applications in every industry. Automotive manufacturers believe it to assemble vehicles. Medical device manufacturers choose it to bond critical components in product assembly. because the industry continues to style lighter, thinner, and smaller products, 3M VHB tape delivers a light-weight permanent bond that doesn’t negatively impact product performance.

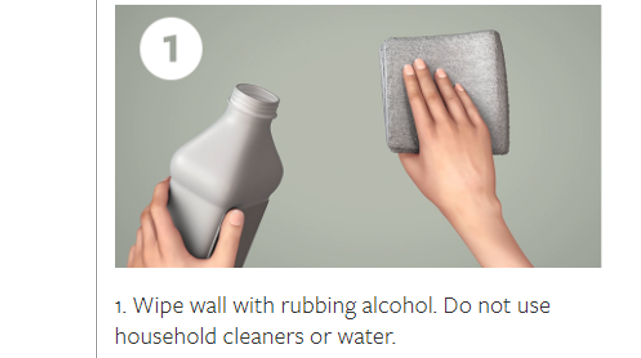

1. 3M VHB tape Surface Preparation — Cleaning

Any adhesive bonds better if the substrate surface is clean, saving time and problems down the road. Use a disposable towel or cloth and one among two solvents: 1) isopropanol solution (70% IPA, 30% water) for dust, dirt, and fingerprints; or 2) acetone for greasy surfaces.

Steps:

If there are tough spots, quickly pre-clean these

Remove contaminants with the wet towel/cloth

Wipe with a dry towel/cloth

2. 3M VHB tape Surface Preparation — Priming

In certain situations, priming and abrading (#3 below) can improve how the adhesive sticks to specific substrates: plastics, paints, and substrates with low surface energy. Simply put, the primer creates a replacement surface to enhance adhesion.

Steps:

Depending on the substrate, apply primer to the clean surface using:

a disposable towel followed by a dry towel

a dauber bottle followed by a dry towel

a foam brush

Let dry before taping

3. 3M VHB tape Surface Preparation — Abrading

Abrasion is usually used on surfaces with heavy levels of dirt or oxides, to make additional area , or to smooth a textured surface for improved contact.

Steps:

Determine the abrasion needed:

for light abrasion, used a hand pad or an L-abrader tool

for powered abrasion, use a right-angle grinder or dual-action sander with a coated abrasive

Clean the substrate after abrading; all debris should be faraway from the bond area

4. 3M VHB tape Application

Determine the simplest application method for your situation by considering your specific application and production volume. Then use the proper tape application equipment.

Steps (by hand):

Place the tape at the sting of the surface, applying constant pressure (at least 15 lbs) as you lay it right down to ensure good contact

Remove the protective liner

Steps (by hand tape applicator):

Same steps as above, but a hand-held applicator is employed rather than bare hands

Steps (by push-through laminator):

Push substrate pieces through the laminator

Laminator applies tape and pressure

Manually cut the tape between pieces

5. 3M VHB tape Automated Tape Application

There are two levels of automated application:

For linear application, a machine tapes pieces that expire a conveyor

For complicated applications, a robot arm applies the tape in multiple locations on every piece; die-cut pieces and tape strips, for instance

6. 3M VHB tape Applying Final Pressure

Applying pressure of greater than 15 psi across the width of the tape is required to realize optimal “wet-out” or acceptable contact. A handheld pressure roller or J-roller can do the work .

7. 3M VHB tape Tape Removal

You may need to remove 3M VHB tape from a substrate due to an application error or repair.

Steps:

Apply isopropanol to the bond’s edge; this lubricates the cutter and prevents rebonding of separated tape

Using an oscillating tool, cut the tape ⅛” to ¼” deep at each pass

Once components are separated, tape residue are often removed use the oscillating tool

Use adhesive remover for any remaining residue: spray it on, let it soak, scrub with a hand pad, remove residue, wipe clean with a towel or cloth

admin

admin  2024-08-23

2024-08-23