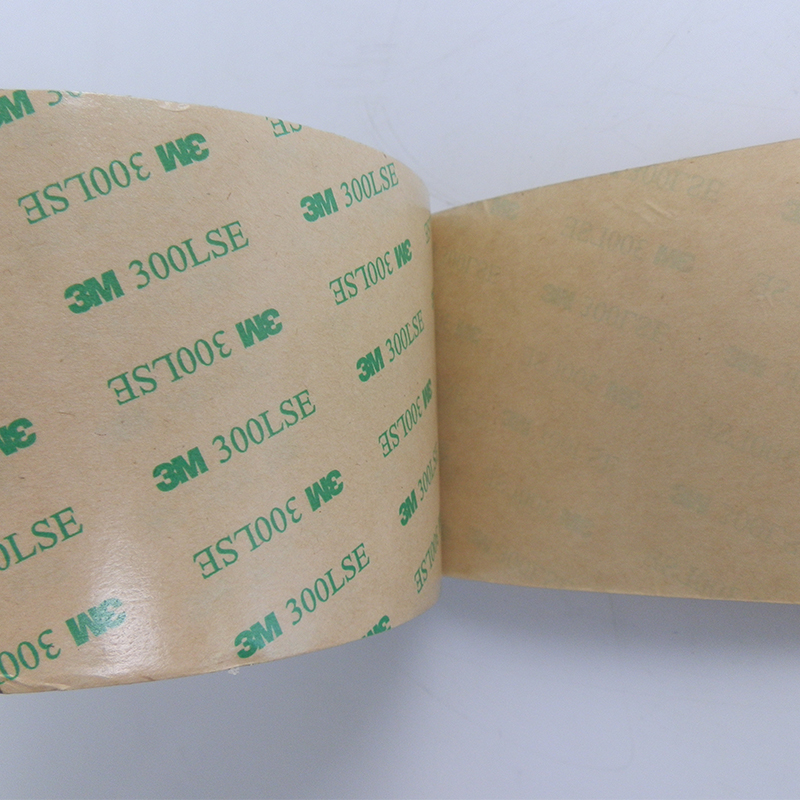

3M double-sided adhesive tape

is widely used in computers, mobile phones, communications, household appliances, audio-visual equipment, automobiles and other products. It should be selected according to the requirements of the applied products and the environment.

Please refer to the following instructions:

1. Non-woven fabric base material has good double-sided adhesive and processing property, general long-term temperature resistance 70-80℃, short-term temperature resistance 100-120℃, thickness is generally 0.08-0.15mm, suitable for the adhesive of nameplate, plastic, automobile, mobile phone, electrical appliances, sponge, rubber, signage, paper products, toys and other industries, home appliances and electronic instrument parts assembly, display lens.

2, no substrate double-sided adhesive has excellent adhesion effect can prevent falling off and excellent waterproof performance, good processing, good temperature resistance, short-term temperature resistance 204-230℃, general long-term temperature resistance 120-145℃, thickness is generally 0.05-0.13mm, suitable for the nameplate, panel, decorative parts of the bonding.

3, PET substrate double-sided adhesive has good temperature resistance and shear resistance, generally long-term temperature resistance 100-125℃, short-term temperature resistance 150-200℃, thickness is generally 0.048-0.2mm, suitable for the label board, LCD, decorations, decorative parts of the bonding.

4. Foam base material double-sided adhesive has soft, good adhesion, good initial adhesion and adhesion, good solvent resistance and uv resistance, general thickness of 0.4-1.0mm, short-term temperature resistance 130-150℃, long-term temperature resistance 80-93℃, suitable for adhesion of air conditioners, office furniture, communication products, can replace the screw fixation design, make the product more beautiful.

admin

admin  2024-08-23

2024-08-23